30

2022

-

11

Reasons for Wrinkling in Aluminum Profile Bending and Stretching

Aluminum profile bending is a very common component in the construction process, and profile bending is suitable for various types of profiles.

Aluminum profile bending is a very common component in the construction process, and profile bending is suitable for various types of profiles. The ratio of width to thickness of a rectangular cross-section profile is the main factor affecting the occurrence of wrinkling and is the main cause of material performance wrinkling.

Nowadays, many people have discovered and studied the relationship between the bending of rectangular cross-section aluminum profiles and the wrinkling of rectangular plates. In profiles, they have different types, materials, and many different cross-sections, which will form differences between wrinkles. Aluminum profiles also exhibit wrinkling during arc bending and tension bending, and corresponding research has been conducted. It has been found that pure bending of profiles also exhibits wrinkling behavior, and they differ in many aspects. Based on the theory of plastic deformation, a theoretical analysis model for pure bending deformation wrinkling and section distortion was proposed using the energy method, and the model was experimentally verified. This is the study of pure bending deformation wrinkling.

During the bending process of aluminum profiles, some parts below the neutral layer are subjected to longitudinal pressure, while the radial and width directions are also subjected to compressive stress. Under the three aspects of compressive stress in the profile, longitudinal shrinkage and radial increase occur. In severe cases, it can cause significant deformation and wrinkling, as well as wrinkles appearing inside the contour. The compression at both ends of the thin-walled shell can also cause wrinkling. These are all related to pressure, thickness, and width, and the smaller the proportion between them, the more prone they are to wrinkle instability. This increases the thickness of the inner web plate of the aluminum profile bending arc, while also improving its wrinkle resistance.. When the cross-sectional shape is relatively stable, tension bending can increase the tensile force to effectively prevent wrinkling. The production and processing of aluminum profile bending arc is not only a simple process, but also requires skilled technology.

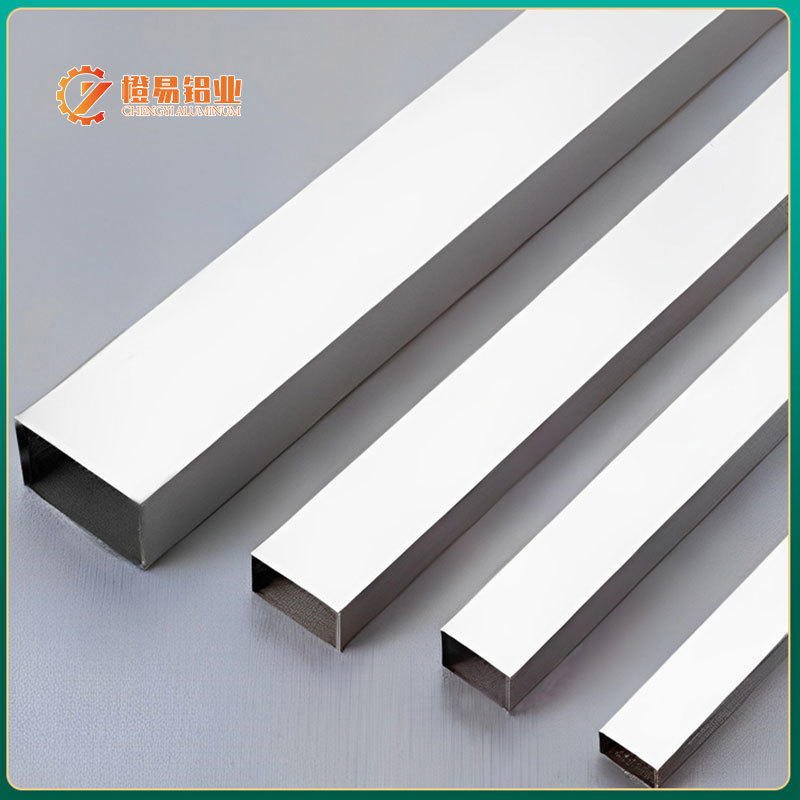

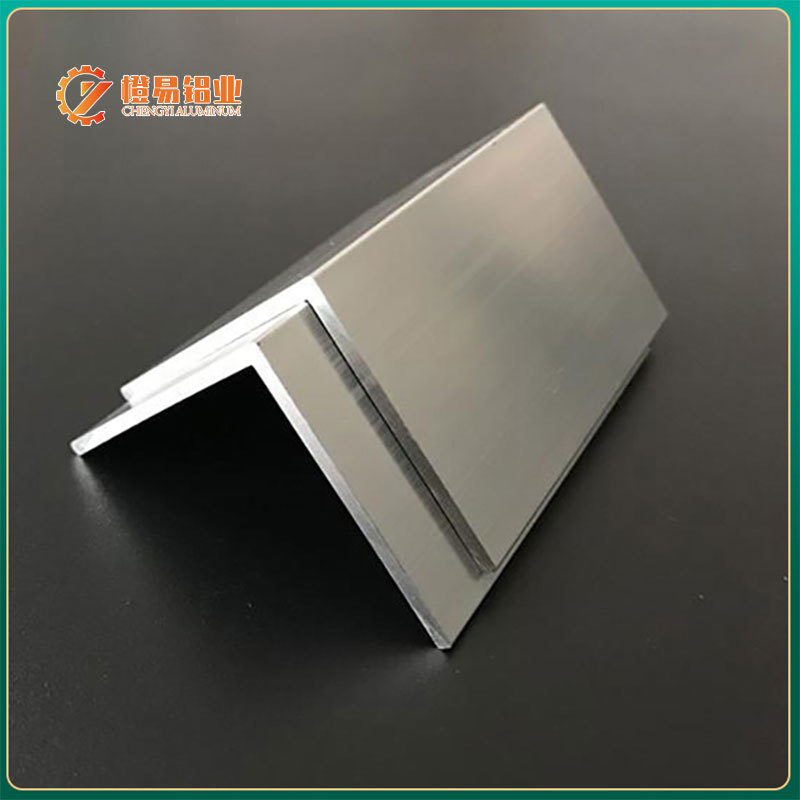

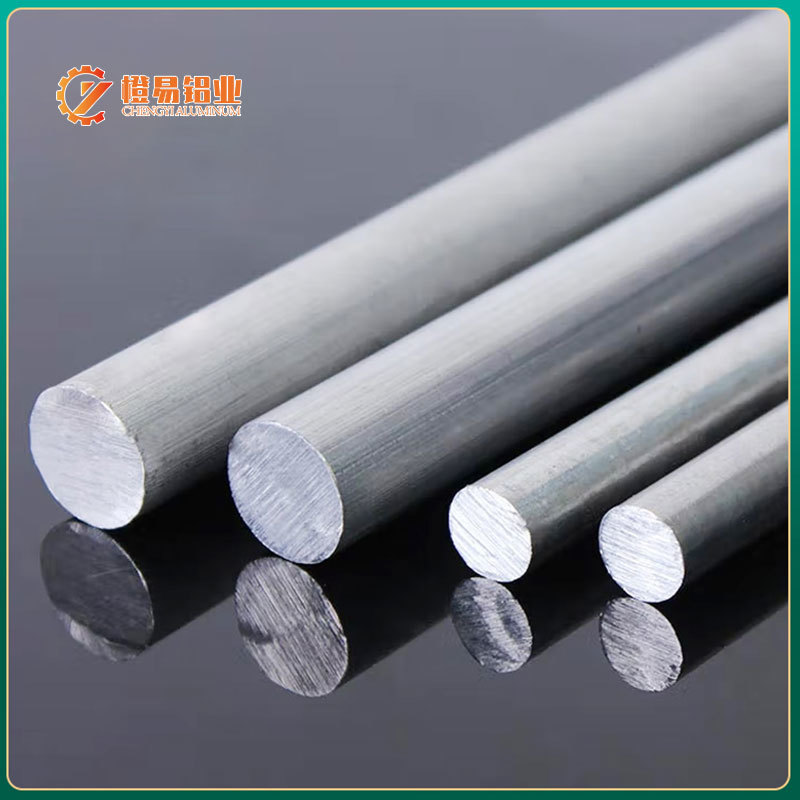

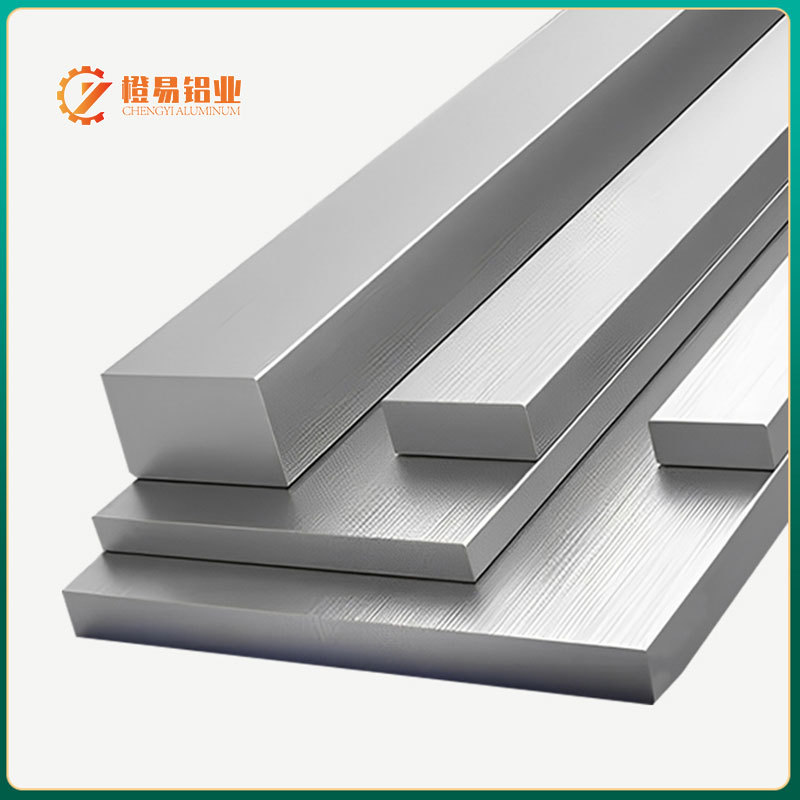

Related Products