22

2020

-

05

How to solve surface damage in aluminum profile bending and arc machining?

Currently, the development of the aluminum profile bending and arc processing industry has also promoted the continuous development of bending and arc processing technology.

Currently, the development of the aluminum profile bending and arc processing industry has also promoted the continuous development of bending and arc processing technology. Aluminum profile bending and rolling is a bending method that uses three rollers for bending. The middle drive wheel is a roller, and the driven wheel is the other two. The bending of the curvature radius is achieved through the distance between the driving wheel and the driven wheel, and its working principle is the same as that of thin plate rolling. Both curved circular and tubular parts are suitable for this method.

The main reasons for surface damage of aluminum profiles caused by arc bending processing manufacturers are as follows:

1. There are debris or debris attached to the surface of the ingot. When there is a large amount of segregation on the surface of the ingot and the ingot is not homogenized or the homogenization effect is poor, there will be a certain amount of hard metal particles in the ingot. When metal flows through the working strip during the extrusion process, these segregated buoys or hard metal particles will adhere to the surface of the working strip or cause damage to the working strip, and also cause scratches on the surface of the profile;

2. There are debris on the mold cavity or working strip, and the hardness of the working strip of the mold is low. When squeezed, it can damage the surface of the working strip and scratch the profile;

3. There are exposed metal or hard inclusions in the discharge guide rail or rotating bed, which can scratch the surface of the profile when they come into contact with it;

4. When the profile is transported from the discharge track to the rotary bed using a fork rod, the profile may be damaged due to excessive speed;

5. Scratches caused by manually dragging profiles on the bed;

6. Damage caused by mutual friction or compression between profiles during transportation.

Solution to avoid surface damage caused by bending of aluminum profiles:

1. Strengthen the control of ingot quality;

2. Improve the quality of mold repair, regularly nitriding the mold and strictly implementing the nitriding process;

3. Use soft felt to isolate the profile from the auxiliary equipment, and minimize contact damage between the profile and the auxiliary equipment as much as possible;

4. During production, it is necessary to handle the profiles with care and avoid dragging or flipping them randomly as much as possible;

5. Reasonably arrange the profiles in the material frame to avoid mutual friction as much as possible.

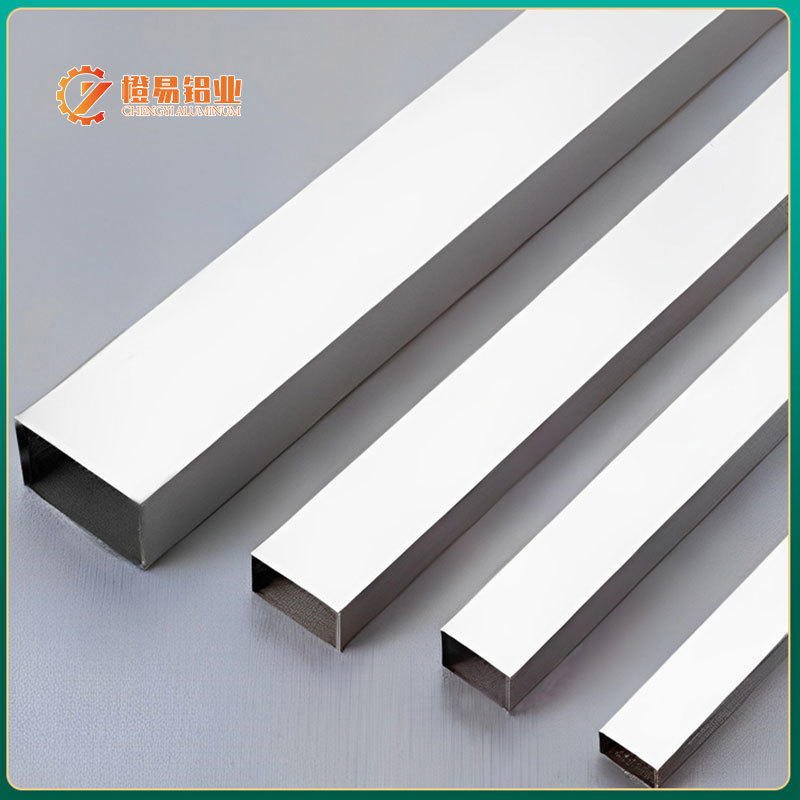

Related Products