15

2020

-

05

How to judge the quality of aluminum materials used in automobiles?

The quality of aluminum used in automobiles is good or bad, and the amount of aluminum used at a time is huge, making it impossible to inspect each item individually.

The quality of aluminum used in automobiles is good or bad, and the amount of aluminum used at a time is huge, making it impossible to inspect each item individually. It is important to choose a good manufacturer in order to reduce unnecessary trouble. Therefore, in order to accurately determine the qualifications of automotive aluminum manufacturers, the first step is to understand the several major factors that affect the quality of automotive aluminum.

Usually, the quality of aluminum materials used in automobiles mainly depends on:

1. Alloying element

Regular aluminum manufacturers have internal standards when preparing alloy components, which are within the range of various element contents. Only alloys made with qualified formulas can ensure quality, otherwise how to process them in the future will not improve the quality.

2. Aluminum alloy melting furnace

How aluminum alloys are melted and what furnace to use are also crucial. The quality of alloys prepared in primitive coal fired furnaces and modern circular furnaces is absolutely different.

3. Alloy casting

The level of domestic casting equipment also varies greatly. Compared to using advanced casting equipment, using outdated equipment has the advantages of low investment and production costs, which is also one of the reasons for the large price difference in the sales of aluminum materials for automobiles.

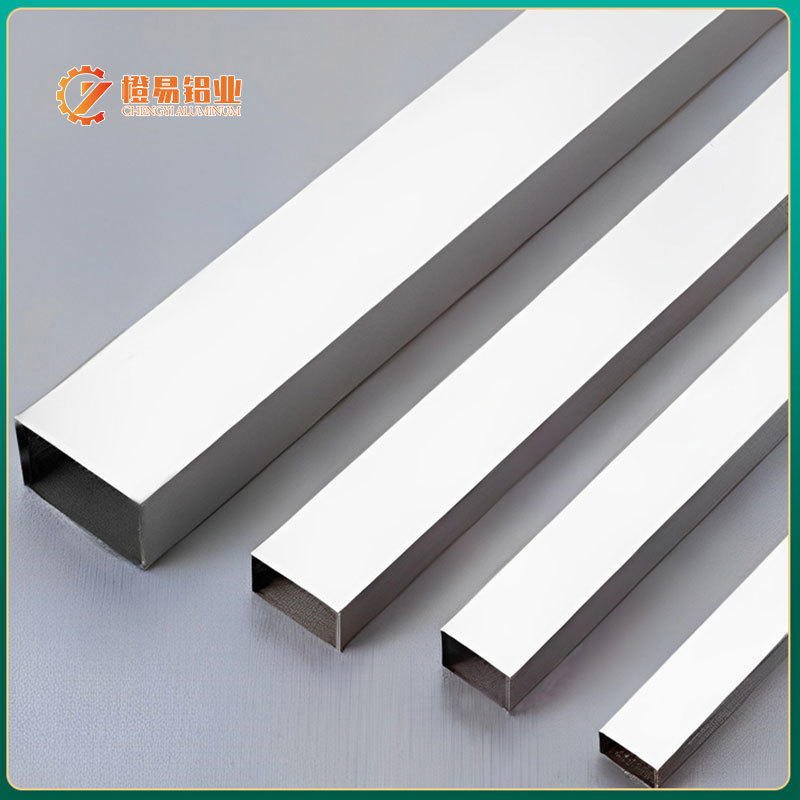

4. Profile extrusion

There are various types of profile extrusion machines in China, with significant differences in grade, which is also the highest in the world. There are factories with their own simple extrusion machines, some with plastic extrusion machine modifications, and a small number of domestically produced ones. Good and bad extruders, the same casting rod, will never produce the same quality of extruded profiles.

In addition, to obtain a more intuitive and rapid understanding of the quality of aluminum materials used in automobiles, the following methods can also be used for simple judgment:

1. Check oxidation degree: When purchasing, you can lightly scratch the surface of the profile to see if the oxide film on its surface can be wiped off. Customers can operate on the materials displayed by the merchant;

2. Chromaticity: The color of the same aluminum alloy profile should be consistent. If the color difference is obvious, it should not be chosen. Generally, the cross-sectional color of normal aluminum alloy profiles is silver white, with a uniform texture. If the color is dark, it can be determined that it is made from recycled aluminum or scrap aluminum by furnace forging;

3. Check flatness: Check the surface of aluminum alloy profiles to ensure there are no dents or bulges. Aluminum materials for automobiles processed by legitimate manufacturers have a flat and bright surface.

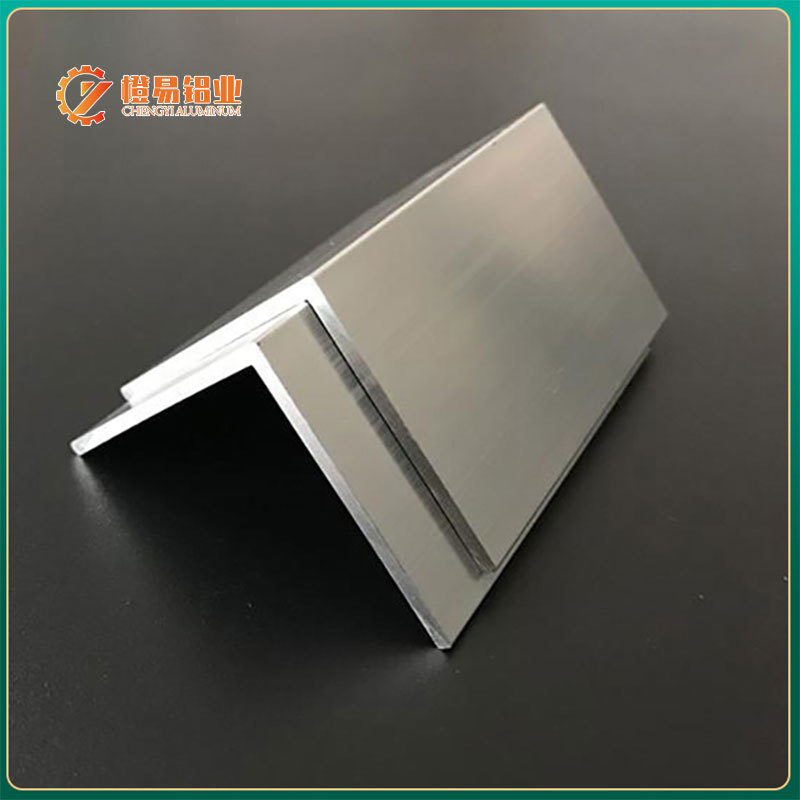

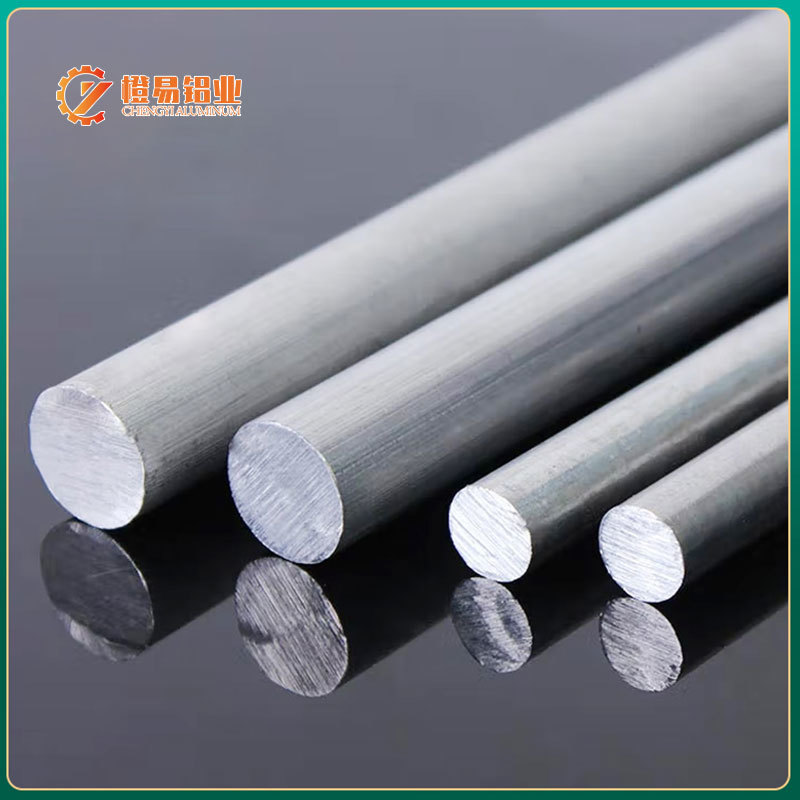

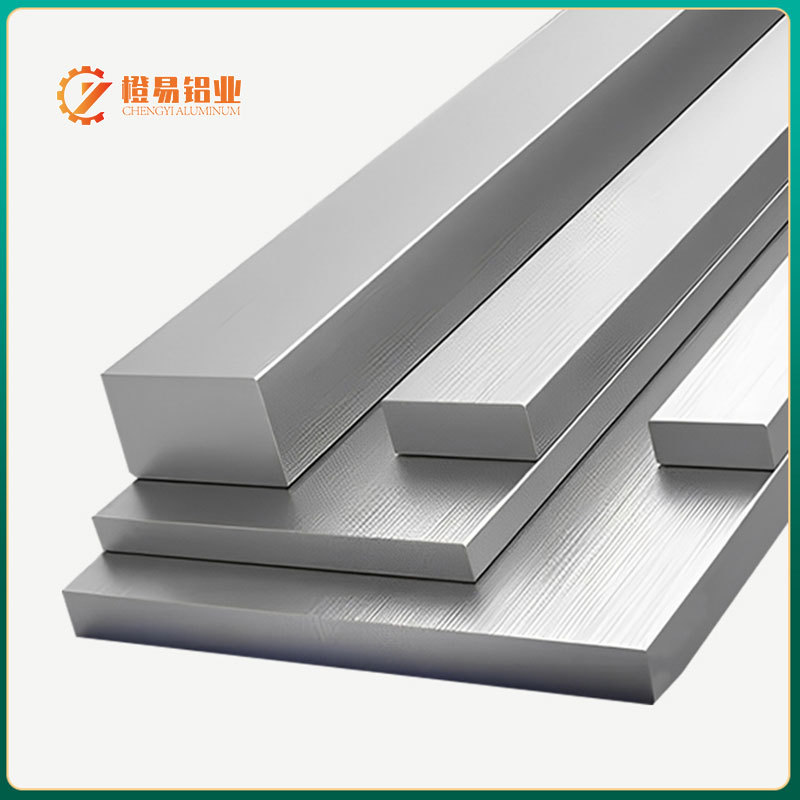

Related Products