13

2020

-

05

The Help of Aluminum on Automobile Lightweight

With the worsening air pollution problem, decreasing resources, and the rapid development of automobiles, aluminum materials for automobiles have also become a popular material in automobile manufacturing.

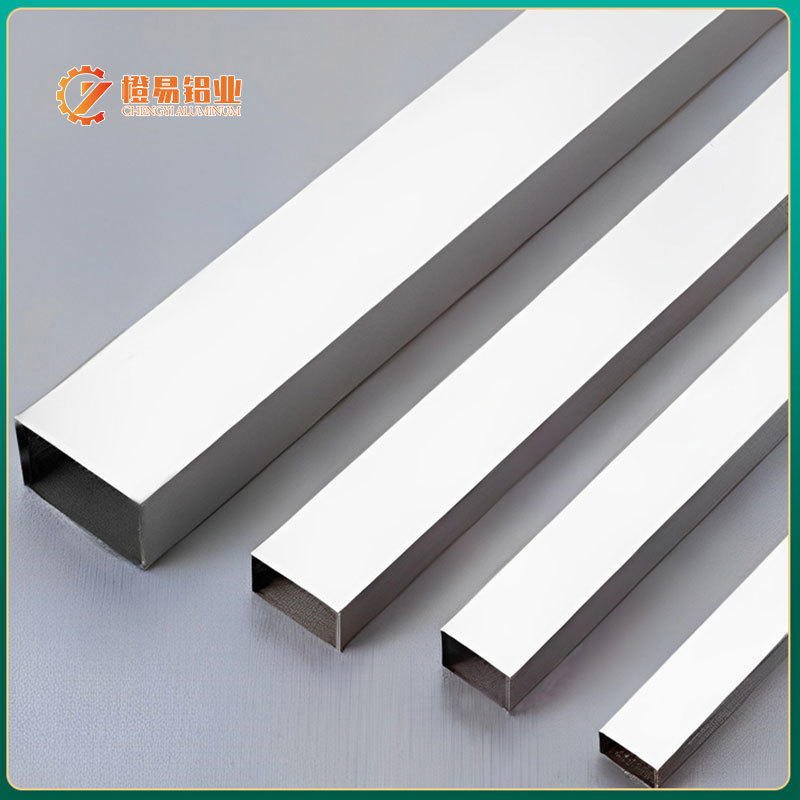

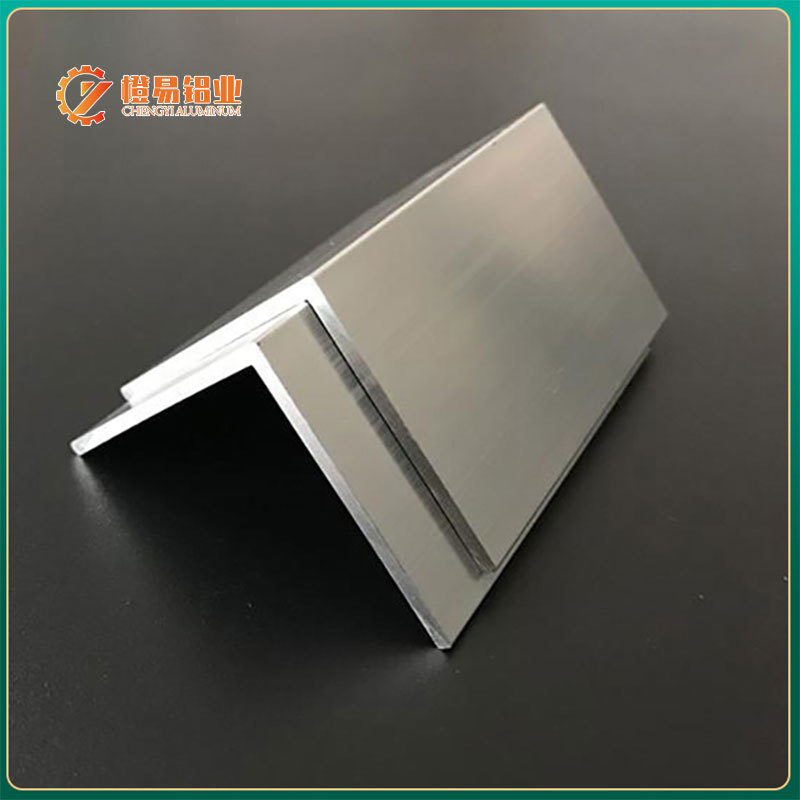

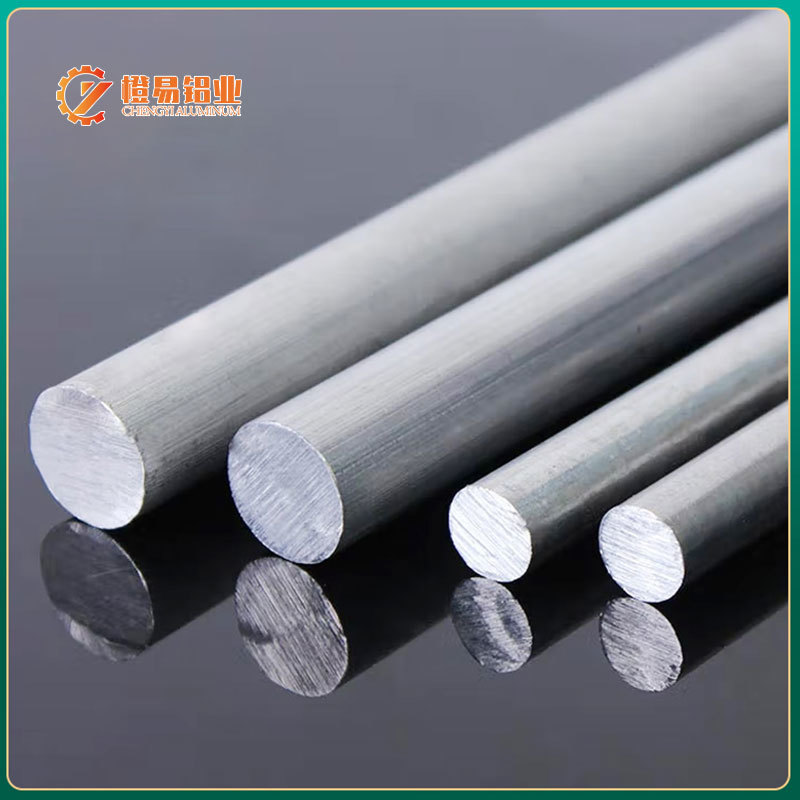

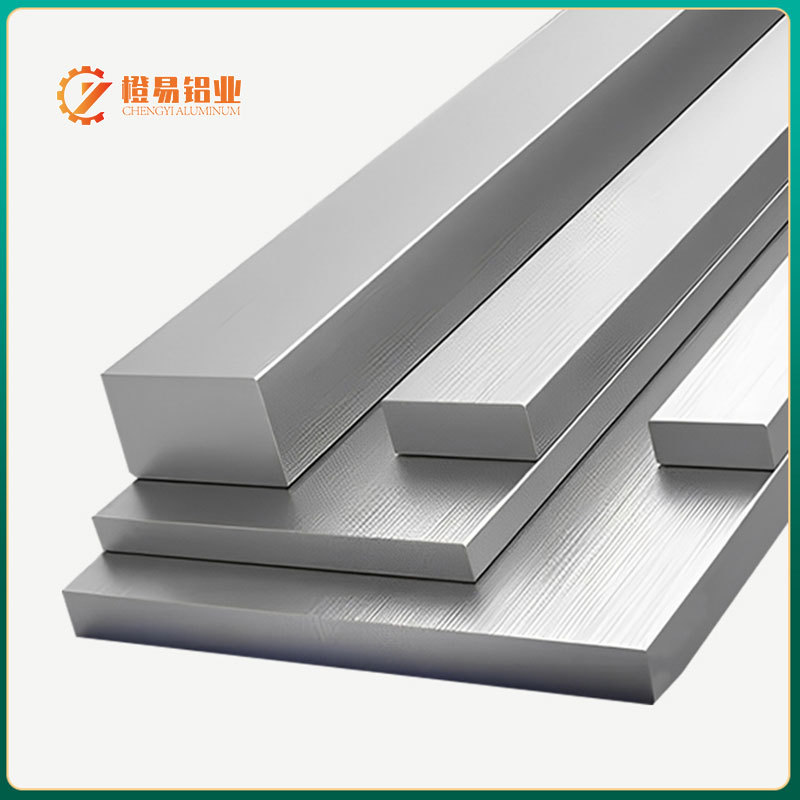

With the worsening air pollution problem, decreasing resources, and the rapid development of automobiles, aluminum materials for automobiles have also become a popular material in automobile manufacturing. Aluminum materials used in automobiles have low density, high strength, close to or even higher than steel, good plasticity, and can be processed into various profiles with excellent conductivity and thermal conductivity. Some automotive aluminum materials can achieve good mechanical, physical, and corrosion resistance through heat treatment. In addition, in order to achieve the goals of reducing pollution and improving fuel economy in the automotive manufacturing industry, it is imperative to reduce vehicle weight. To reduce vehicle weight, it can be achieved by improving the vehicle structure or using lightweight aluminum materials for automobiles.

In recent years, the application of aluminum materials for automobiles has gradually become widespread. Aluminum materials used in automobiles are also used to manufacture engine blocks, cylinder heads, intake manifolds, bearing seats, clutch housings, pistons, car wheels, car bodies, heat exchangers, etc. Its advantages mainly include the following:

1. Significant weight reduction and energy-saving effects. Aluminum has good mechanical properties, with a density only 1/3 that of steel, and good thermal conductivity, second only to copper. Its mechanical processing performance is 4.5 times that of iron, and its naturally formed oxide film, aluminum oxide, has good corrosion resistance. Unlike steel, aluminum has the characteristics of corrosion resistance and rusting, making it an ideal material for achieving lightweight in automobiles.

2. Improve passenger comfort and safety. Although it is necessary to achieve lightweight, it is also necessary to ensure the safety and comfort of passengers. Aluminum materials used in automobiles reduce the weight of the car without reducing its capacity, thereby reducing the self weight of the body and further making the driving of the car more stable and comfortable. In addition, due to its excellent energy absorption, aluminum has significant advantages in collision safety. During a collision, the deformation area at the front of the car will wrinkle and absorb a large amount of impact force, thereby protecting the driver and passengers behind.

3. Aluminum is easy to recycle. Due to the protective effect of the surface aluminum oxide film, automotive aluminum materials have almost no corrosion during use, making their recycling value extremely high.

Related Products